Under the deal, rare earth magnets will be developed from 100% recycled materials at MP’s flagship manufacturing plant in Hillwood’s AllianceTexas development. Magnet shipments are slated to begin in 2027 and will ramp up to support “hundreds of millions of Apple devices,” MP said.

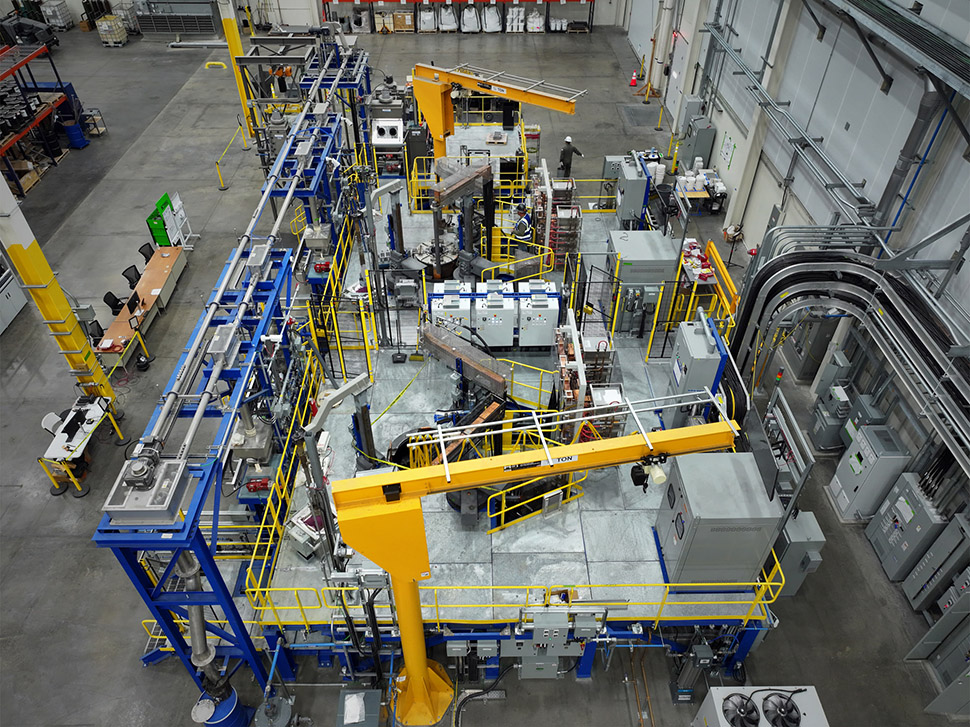

A front view of Independence, MP Materials’ state-of-the-art rare earth magnet manufacturing facility in Fort Worth [Photo: Business Wire]

Apple has struck a $500 million deal to buy rare earth magnets from Las Vegas-based MP Materials—and the magnets will be developed from 100% recycled materials at MP Materials’ flagship manufacturing plant in Fort Worth.

Rare earth magnets are key components in everything from smartphones to computers to EVs, robots, and energy systems. To create the magnets, MP Materials (NYSE: MP) will use recycled rare earth “feedstock” sourced from post-industrial and end-of-life magnets, with the recycling happening at MP’s Mountain Pass site in California.

Building out Fort Worth plant with lines for Apple products

[Photo: Apple]

As part of the deal, MP said it will “significantly expand” the capacity of its Fort Worth plant with a series of new neodymium magnet manufacturing lines designed for a range of Apple products.

Magnets created in Fort Worth will then be shipped across the U.S. and all over the world, helping to meet increasing global demand for the material, Apple said—adding that the boost in production will support “dozens of new jobs in advanced manufacturing and R&D.”

The two companies will provide training to develop the workforce needed, “building an entirely new pool of U.S. talent and expertise in magnet manufacturing,” Apple noted.

Magnet shipments are slated to begin in 2027 and will ramp up to support “hundreds of millions of Apple devices,” MP said.

Apple and MP Materials will build out MP’s Fort Worth factory with a series of neodymium magnet manufacturing lines specifically designed for Apple products. [Photo: Apple]

The companies said they will also work together to establish a new “cutting-edge rare earth recycling line” in MP’s Mountain Pass facility, aiming to develop novel magnet materials and innovative processing tech to enhance magnet performance. When it enters operation, the new line will enable MP to take in recycled rare earth feedstock—including rare earth sourced from used electronics and post-industrial scrap—and reprocess it for use in Apple products.

Apple builds on a five-year collaboration

The two companies have already collaborated for nearly five years, piloting advanced recycling tech “that enables recycled rare earth magnets to be processed into material that meets Apple’s exacting standards for performance and design,” Apple said.

“American innovation drives everything we do at Apple, and we’re proud to deepen our investment in the U.S. economy,” Apple CEO Tim Cook said in a statement. “Rare earth materials are essential for making advanced technology, and this partnership will help strengthen the supply of these vital materials here in the United States. We couldn’t be more excited about the future of American manufacturing, and we will continue to invest in the ingenuity, creativity, and innovative spirit of the American people.”

Apple said its $500 million MP commitment is part of its pledge to spend more than $500 billion in the U.S. over the next four years.

“We’re proud to partner with Apple to launch MP’s recycling platform and scale up our magnetics business,” James Litinsky, the founder, chairman and CEO of MP Materials, said in a statement. “This collaboration deepens our vertical integration, strengthens supply chain resilience, and reinforces America’s industrial capacity at a pivotal moment.”

Aerial view of MP Materials’ rare earth magnet facility in Fort Worth [Photo: MP]

Apple first used recycle rare earth elements in the iPhone 11

Apple said it pioneered the use of recycled rare earth elements in consumer electronics, introducing them in 2019 in the iPhone 11’s Taptic engine.

Today, “nearly all magnets across Apple devices” are made with 100% recycled rare earth elements, the company said—adding that its collaboration with MP “will help secure domestic supply of this critical material, strengthen the U.S. rare earth industry’s capabilities to capture more raw material, and advance environmental progress with innovative recycling methods.”

MP Materials said the new Apple deal advances its own mission to restore the full rare earth supply chain to the United States “while raising the global standard for sustainable production.”

By recovering rare earth elements from recycled materials, MP said it aims to “reduce waste, conserve natural resources, and drive cost-competitive domestic magnet production.”

Fort Worth plant began production in January

In January, MP Materials launched commercial production at its Fort Worth plant, commencing neodymium-praseodymium (NdPr) metal and trial production of automotive-grade, sintered neodymium-iron-boron (NdFeB) magnets. At the time, MP said a key customer was General Motors and its electric vehicles.

NdFeB magnets are the world’s most powerful and efficient permanent magnets—serving as essential components in vehicles, drones, robotics, electronics, and aerospace and defense systems. But the U.S. has relied almost entirely on foreign sources for these critical inputs “for decades,” MP Materials said in January.

The company aimed to turn that around with its Fort Worth plant, which it calls “the United States’ first fully integrated rare earth metal, alloy, and magnet manufacturing” facility.

Ross Perot Jr., chairman of The Perot Group, and MP Materials co-founder and CEO James Litinsky at the 2022 groundbreaking for MP’s new rare earth magnet factory at AllianceTexas in Fort Worth. [Photo: MP Materials]

Dallas Innovates first wrote about MP’s 200,000-square-foot Fort Worth plant in 2021, noting its planned location within Hillwood’s AllianceTexas development and its role as the business and engineering headquarters for MP’s magnetics division, MP Magnetics. At the time, MP said the plant could ultimately power some 500,000 EV motors every year and restore a “full integrated U.S. supply chain.”

Construction on the plant began in 2022.

Content retrieved from: https://dallasinnovates.com/apple-announces-500m-deal-to-buy-rare-earth-magnets-from-mp-materials-fort-worth-plant/.