Las Vegas-based MP Materials said the achievements at its Fort Worth facility bring the U.S. closer to reestablishing “a fully integrated, domestic supply chain for these critical components for the first time in decades.” A key MP customer: General Motors and its electric vehicles.

by David Seeley and Lance Murray in Dallas Innovates | Jan 22, 2025

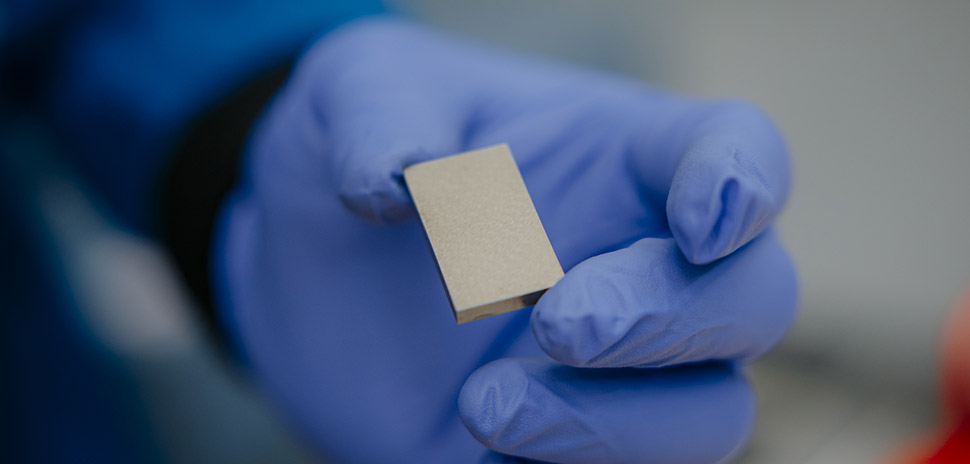

MP Materials (NYSE: MP) has achieved a milestone in “restoring the U.S. rare earth magnet supply chain” at its flagship Independence facility in Fort Worth, the company announced. The facility has begun commercial production of neodymium-praseodymium (NdPr) metal and trial production of automotive-grade, sintered neodymium-iron-boron (NdFeB) magnets. A leading MP customer: General Motors and its electric vehicles.

NdFeB magnets are the world’s most powerful and efficient permanent magnets—serving as essential components in vehicles, drones, robotics, electronics, and aerospace and defense systems. But the U.S. has relied almost entirely on foreign sources for these critical inputs “for decades,” MP Materials said.

The Las Vegas-based company said it’s addressing that gap by building the Fort Worth plant, which it calls “the United States’ first fully integrated rare earth metal, alloy, and magnet manufacturing.”

MP began building the 200,000-SF plant in Hillwood’s AllianceTexas development in April 2022. Last March, MP received a $58.5 million award in the form of a 48C Advanced Energy Project tax credit allocation issued by the IRS and U.S. Treasury Department. The award was meant to advance MP’s planned delivery of products for General Motors’ EVs.

MP said its newly announced production achievements are bringing the U.S. closer to reestablishing “a fully integrated, domestic supply chain for these critical components for the first time in decades.”

Marking ‘a major step forward’

Electrolysis cells at MP Materials’ Fort Worth Independence facility convert rare earth oxides to high-purity metals essential for magnet production. [Photo: Business Wire]

“This milestone marks a major step forward in restoring a fully integrated rare earth magnet supply chain in the United States,” James Litinsky, founder, chairman, and CEO of MP Materials, said in a statement. “With record-setting upstream and midstream production at Mountain Pass and both metal and magnet production underway at Independence, we’ve reached a significant turning point for MP and U.S. competitiveness in a vital sector.”

MP’s trial production of magnets in Fort Worth “will switch to commercial production towards the end of the year,” Chief Communications Officer Matt Sloustcher told Dallas Innovates, adding that the magnets “will power the drive motors in GM electric vehicles.”

The Fort Worth plant could ultimately power some 500,000 EV motors every year, the company said in 2021.

Record-setting production at Mountain Pass

With commercial NdPr metal production already online and trial production of sintered magnets underway, the Fort Worth Independence facility is poised to produce around 1,000 metric tons of finished NdFeB magnets per year, with a gradual production ramp beginning in late 2025, the company said.

The Fort Worth facility will supply magnets to General Motors and other manufacturers, sourcing its raw materials from Mountain Pass, MP Materials’ mine and processing facility in California.

Last year, MP Materials achieved record-breaking production at Mountain Pass, the company said, delivering more than 45,000 metric tons of rare earth oxides (REO) contained in concentrate—”an all-time high for U.S. primary production.”

Mountain Pass, America’s only active rare earth mining and processing operation of scale, also set a midstream production record, producing roughly 1,300 metric tons of NdPr oxide in 2024, in addition to cerium, lanthanum, and other separated and refined products, MP said.

Content retrieved from: https://dallasinnovates.com/in-u-s-milestone-mp-materials-begins-producing-rare-earth-magnets-at-fort-worth-facility/.